Grounded Bushing Well

- Material: 6061 T6 Machined Aluminum Billet

- Test Rating: ASTM F855-15

- Grade: 5H & 3H

- Material: 6061 T6 Machined Aluminum Billet

- Test Rating: ASTM F855-15

- Grade: 5H & 3H

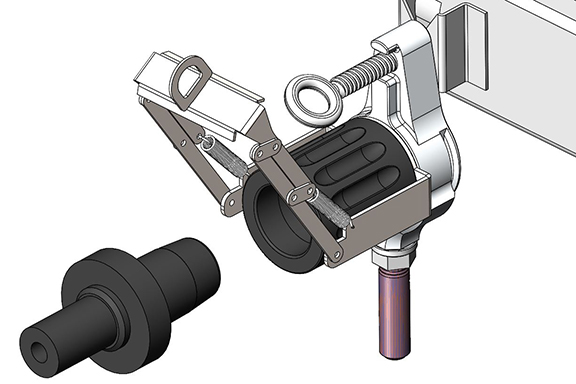

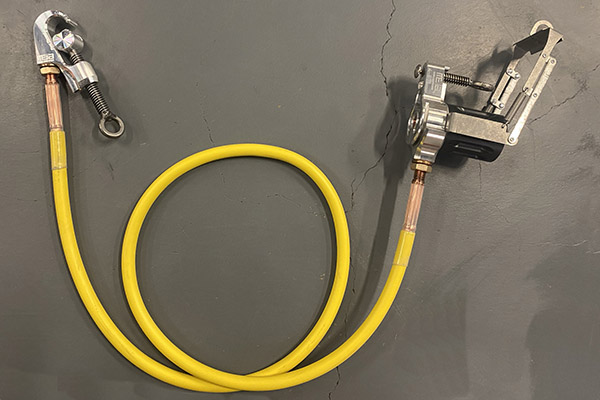

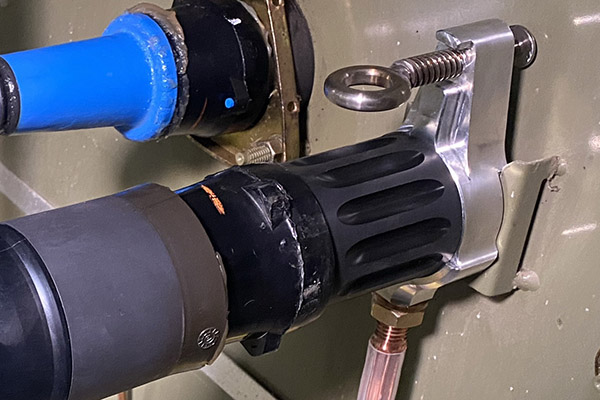

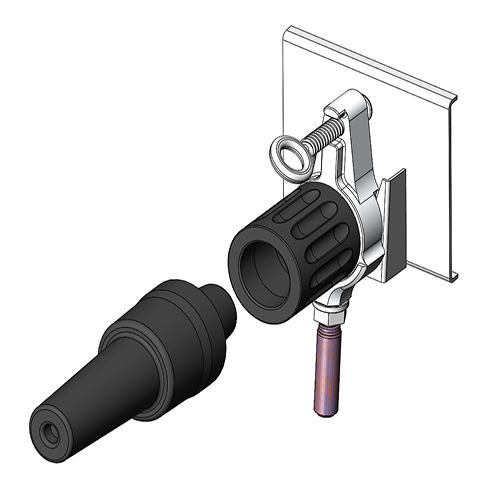

One Device for Two jobs, the GBW securely mounts to both Load Break and Dead Break brackets while housing either bushing.

5X more efficient than standard grounds the GBW is engineered with a high-speed thread requiring only 3 forearm rotations to secure, reducing fatigue and improving safety. Standard load break grounds demand 10-15 rotations to secure.

The GBW’s unique design allows a direct line of sight to the often unused, tiny, dead break bracket, allowing rapid first-time landing while tightening securely to an otherwise flimsy spring hold.

To sustain the explosive mechanical force present in a ground fault, we use a 6061 T6 Machined Billet Aluminum body that is vastly superior to standard aluminum castings for protecting your crew.

Billet 6061 T6 has a 37% better tensile strength (290 MPa vs 180 MPa) and 100% better yield strength (240 MPa vs 100MPa) than standard cast aluminum. The elongation at break of 6061 T6 is twice that of standard cast aluminum (20% vs 10%).