With over a year in development, and patents pending, our latest innovation is the Raptor Overhead Ground Clamp that significantly improves upon the industry’s leading “Duckbill” grounds.

Proof of Concept

In our test lab we conducted trials with different linemen ranging in experience from 30 year vets to first year rookies. Competing against the clock and tasked with a series of phase to phase grounds, they tested the top two competitive duckbill clamps against our Raptor Overhead clamp. The results saw a significant difference. Our Raptor consistently performed on average 40% faster than the others and reduced user errors by 5X!

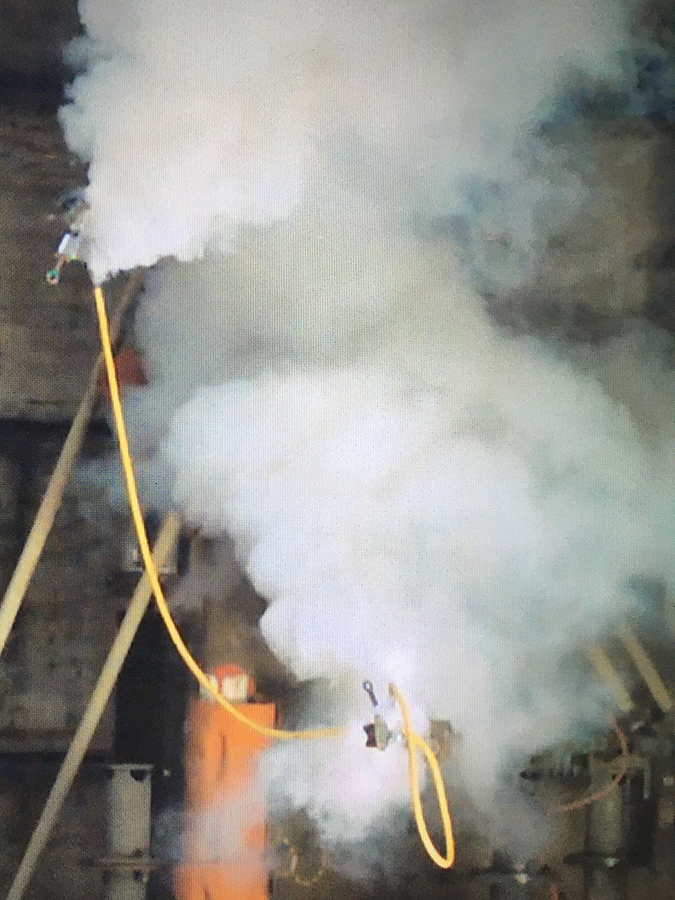

In the ICEE test lab in Vancouver Canada, the Raptor exceeded all expectations and passed certification with flying colors. In an explosive lightening display, 28,000 Volts blasted through the facility vaporizing everything but our clamps. When the smoke cleared the Raptor Overhead Clamps held firm on either end while the 2/0 cable itself was severed and blasted across the facility into a molten heap.

So how did we do it?

With the philosophy of safety first and fatigue being the enemy hazard, we evaluated where the repetitive strain was happening in our linemen and discovered an opportunity for innovation. Existing devices required up to 15 supinations of the forearm to secure and 15 pronations to remove. So, we set out to reduce these numbers.

In brainstorming sessions with seasoned linemen, we thought the ratchet on the hot stick could be used in tandem with a spring somehow, to reduce the tedious rotations required to mount a standard Duckbill clamp. We took that idea and quickly produced a series of prototypes that began a complete process of iterative designs.

The secret lies within a deceptively simple threaded pall that can disengage from the threaded shaft, while letting a compression spring do the work for most of the travel and then re-engage for tightening. Whether grounding on a 1/8” copper wire or a 1” Cable or cluster bracket, the Raptor only requires 1-2 rotations to achieve 40 ft lbs of force, providing a superior hold.